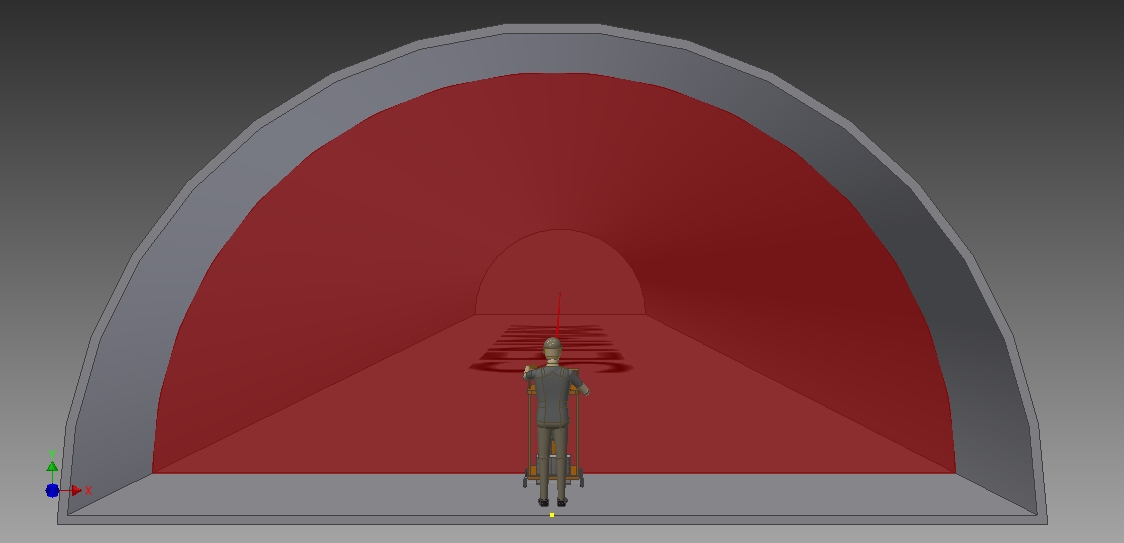

SM-TIS is advanced technology using 3D laser scanner, if the system starts scanning, data collection is displayed in real-time to aid in navigation and to allow the technician to make instantaneous analysis of the infrastructure. Recorded information is used to generate detailed reports including graphics and models of the assets.

That system data provides guidelines on tunnel operations, maintenance, and evaluation that helps to ensure tunnels remain in safe condition and continue to provide reliable levels of service. Our system uses high speed laser scanners to obtain 3D profiles of tunnel, from that 3D profile we can get high-precision measurements. Once digitalized the tunnel data and that can be viewed and analysed offline by operators. Automatic analysis software is available to detect and rate the condition of joints, faulting, cracks, and degraded concrete, wet as well as humid area tunnel linings.

This intelligent and innovative solution accelerates the tunnel maintenance in transportation and mining areas. The inspection system by SENMAX is applicable for monitoring and maintenance of tunnels through 2D/3D profile scanning.

© 2022 SENMAX All Rights Reserved